Our Equipment and Capabilities

The Right People & Tools for Your Job: Soft Goods Manufacturing at its Best

As a custom sewing contractor, you expect that we have the people and equipment to do the job. And we do. As do our competitors. What is unique about LJ Design & Manufacturing’s capabilities isn’t one person or machine, rather, it is the diversity of our team combined with the best equipment and technology. As heavy-duty sewing contractors with industrial fabric cutting capabilities, we are continually investing in this area to ensure that we are staying on the cutting edge (pun intended).

What this means for you is that we aren’t pushing one particular method of manufacturing. We have flexibility and skill which makes us one of the best large sewing project contractors. Each project is evaluated on its own merits and our engineers will select the most efficient, cost-effective method that meets your specifications.

Our Brookfield, WI location is our only location, which means we proudly provide made in the USA contract sewing. This ensures top-notch quality and meticulous attention to detail.

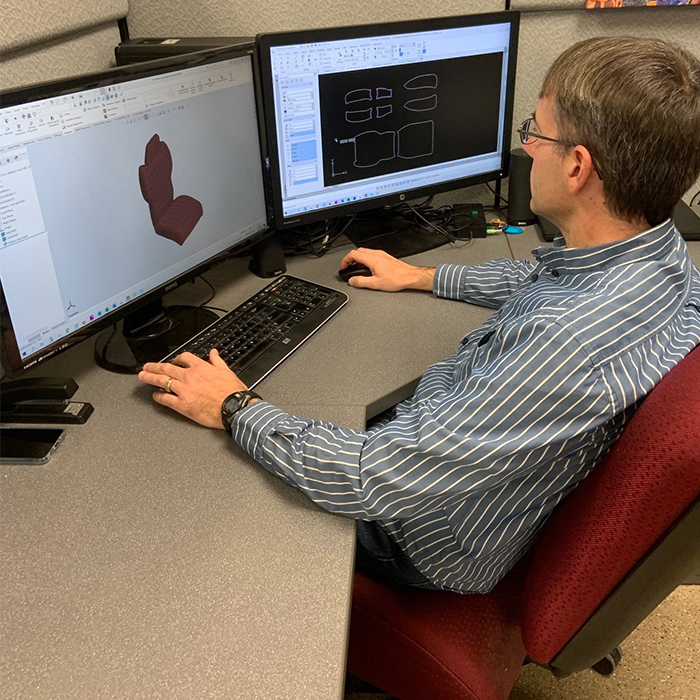

In-house Design & Engineering Team

Our team of engineers specializes in technical soft goods product development. We collaborate with your product development team, which allows you to focus on what you do best. When working with our engineering team you’ll discover:

- Our engineers are expert problem solvers. From issues regarding textile selection, construction, durability, aesthetics and more, they will put their creativity to use for you.

- They will take your product and offer strategic recommendations that focus on scalability, manufacturability, improved customer experiences and increased ROI.

Before mass production begins, we’ll develop a first article of inspection for your approval to ensure a shared vision.

A Stitch for Every Need

While our sewing equipment is impressive, what is more impressive is, the people behind the machine. They bring their years of experience, creativity and problem solving to make us more than just your average custom sewing contractor. Here are a few of stitch types that our production team may use in the manufacturing of your soft goods product:

- Bar Tack

- Box X

- Computerized Pattern Sewing (Large & Small Format)

- Cover Stitch

- Cylinder Bed Lockstitch

- Double Needle Lockstitch

- Double Needle Chain Stitch

- Overlock Serger

- Post Bed Single Needle Lockstitch

- Post Bed Double Needle Lockstitch

- Single Needle Lockstitch

- Walking Foot

- Zig-Zag

Textile Gurus

We have relationships with textile mills globally and can source a wide variety of materials, textiles and hardware to meet your projects specs in the most affordable way possible. We can also work with customer supplied materials. A short list of textiles we frequently work with includes:

- Reinforced coated, laminated and expanded vinyl

- PVC coated polyester, urethane coated nylon

- Silicone coated fiberglass

- Leather

- Silicon, Kevlar®, Nomex®

- Knit fabrics

- Nylons

- Hypalon

- All types of foam

- High temperature materials

CNC Fabric Cutting

CNC fabric cutting (aka programmable fabric cutting) maximizes the material yield by using an algorithm to nest (arrange) the shapes to be cut in the most efficient way possible to reduce material waste. The net result is quicker turnaround times for increased ROI. A few other advantages include:

- Wide load fabric

- Easily accommodates standard fabric roll sizes or sheet widths up to 88-inches.

- Interior cutouts

- Programs intricate interior cutouts.

- Drills different hole sizes and makes notches in your material to mark the location of grommets, snaps or folds

Fabric Die Cutting

Fabric die cutting allows for virtually any shape to be cut with consistency and accuracy. Our presses are a particularly good fit for natural textiles, such as leathers, or for extra thick materials. We can use your existing dies, or our team can create a custom die.

Hot Knife & Cold Knife Cutting

These are great semiautomatic solutions for cutting webbing, binding material, straps, hook-and-loop (such as VELCRO®), and more, while preventing the ends from fraying.